Led Cube 5x5x5 RGB

Not a design from me, but a kit that I bought on the internet. Looked fun to me to build one, but you can forget the “fun” word very fast. What a hell of a job to soldering all the leds to the wires.

According the manual it was for an experience solderer 3 hours work. I can say I’m very experience, but it took me 9 hours.

Straighten all the wires was already a lot of work, after that you need to solder 5x5x5x4=500 pins from the leds to the wires.

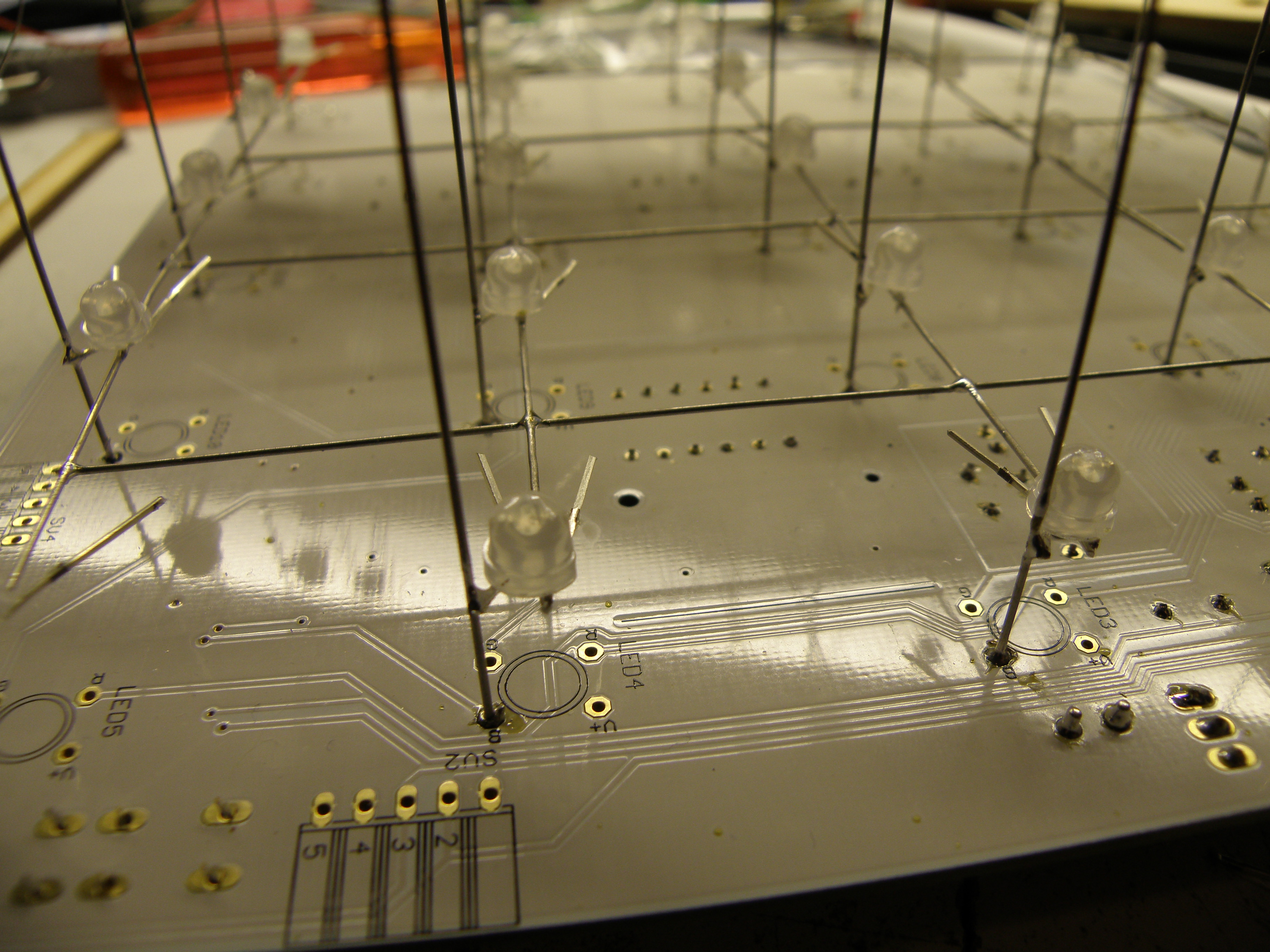

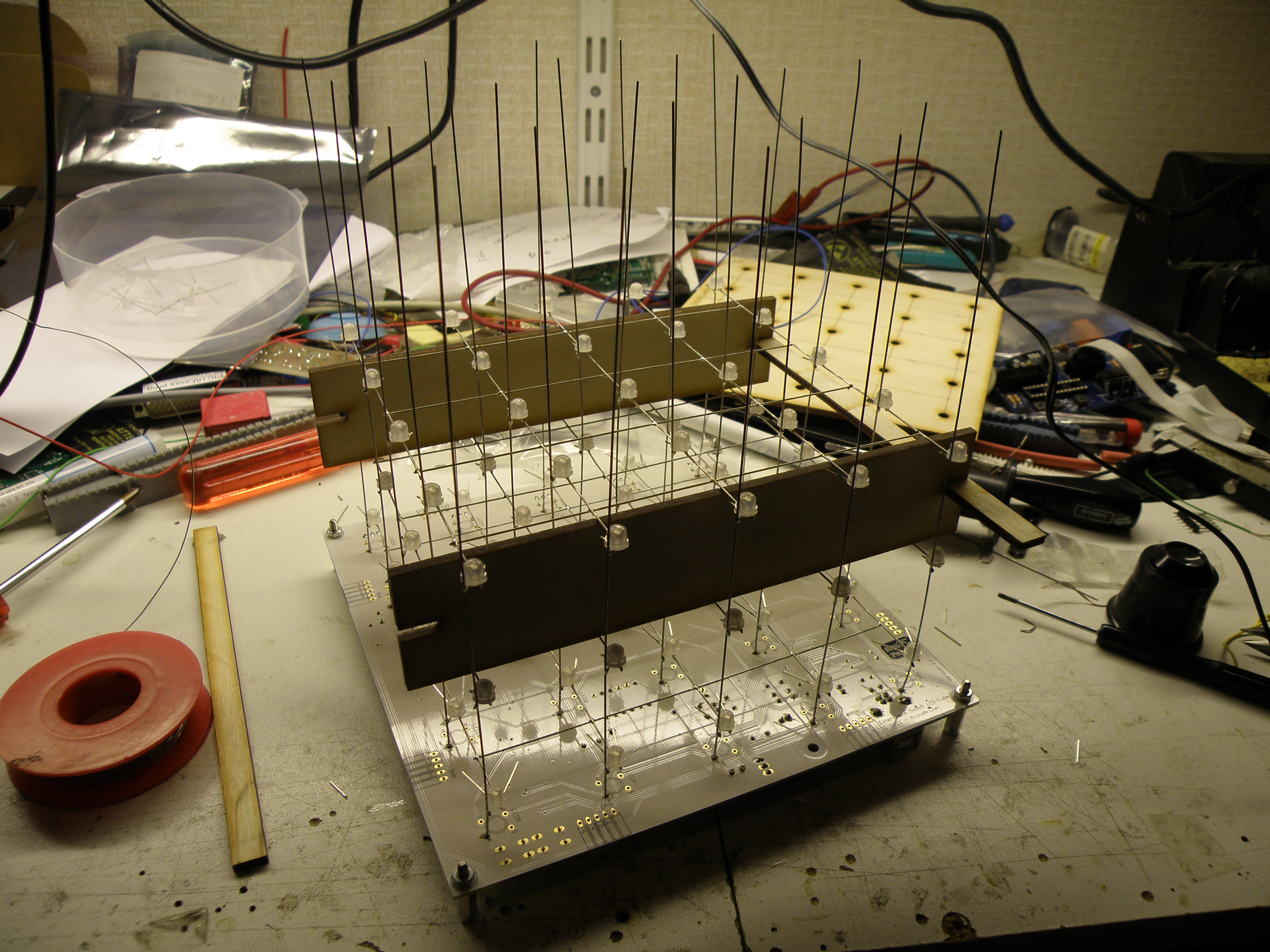

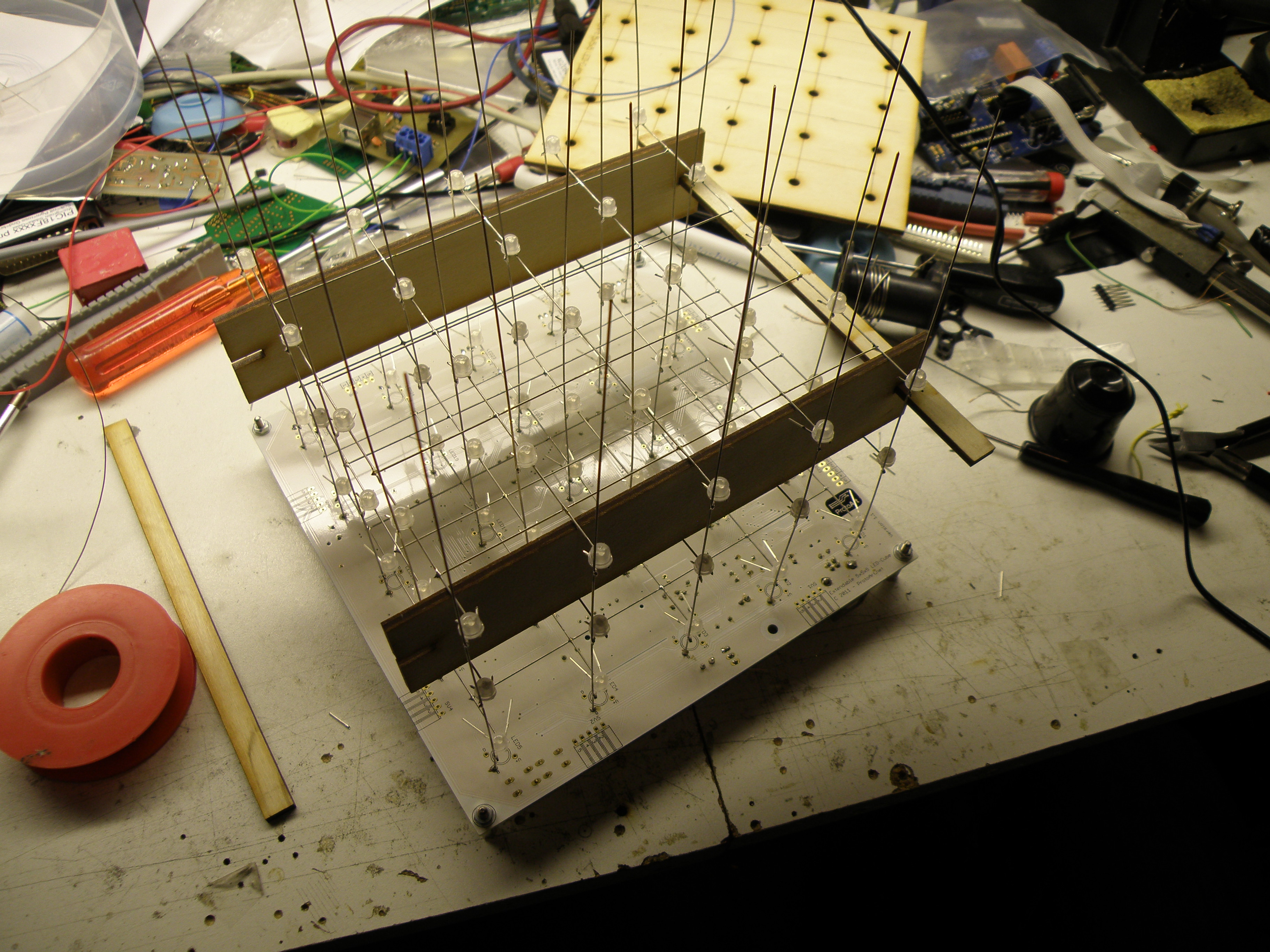

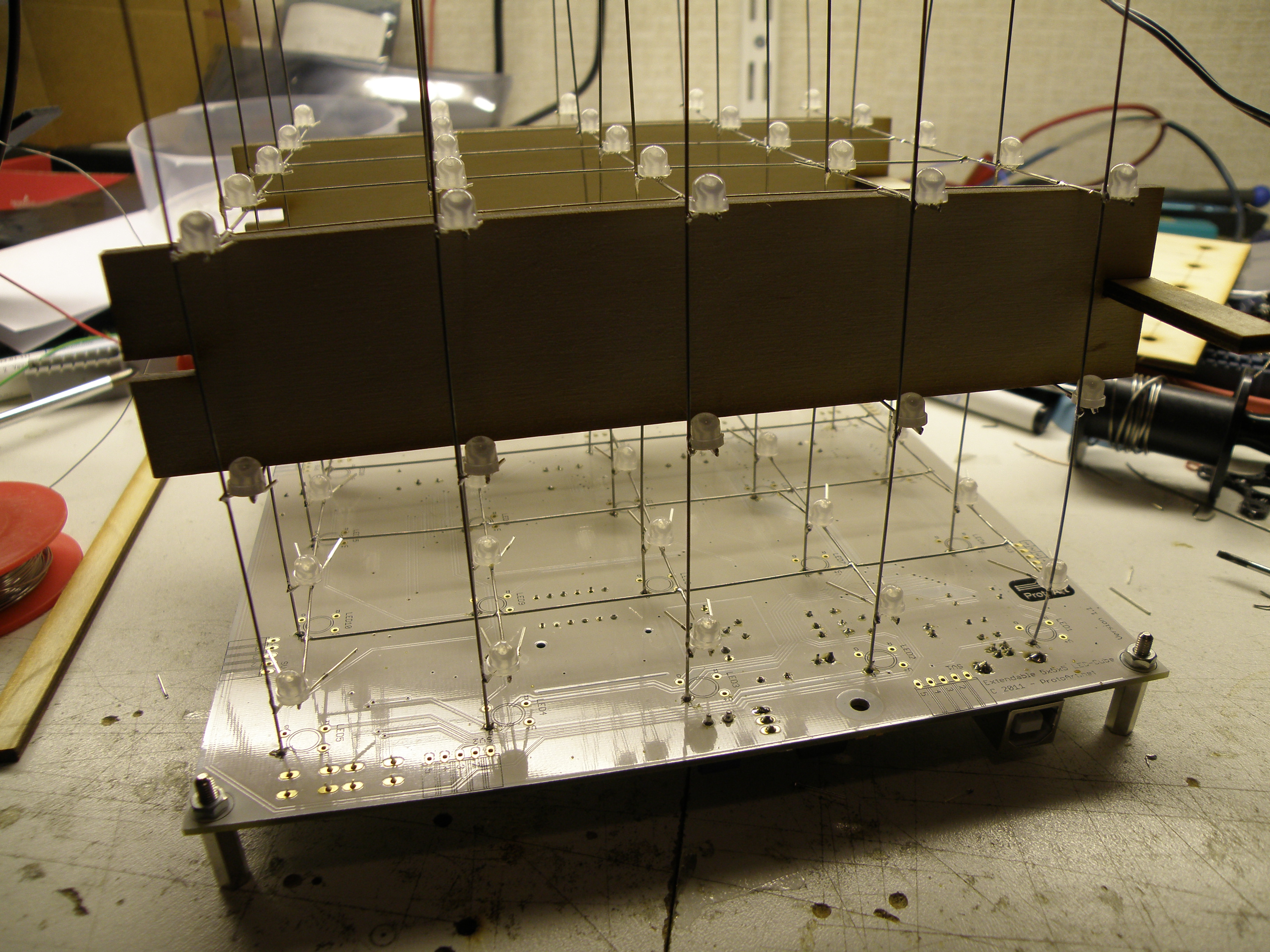

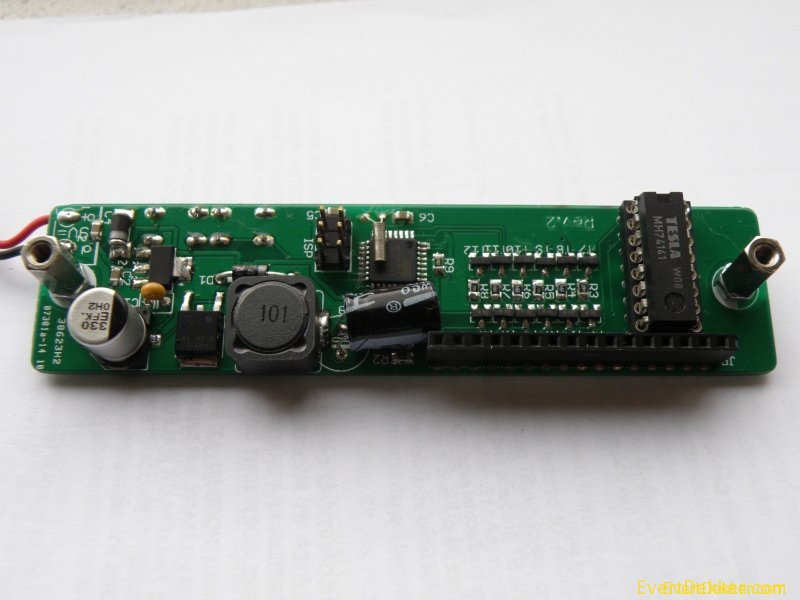

The first step was making the layers. For this they provided a die where you put the leds upside down in and then solder the common frame to all the leds in a matrix.

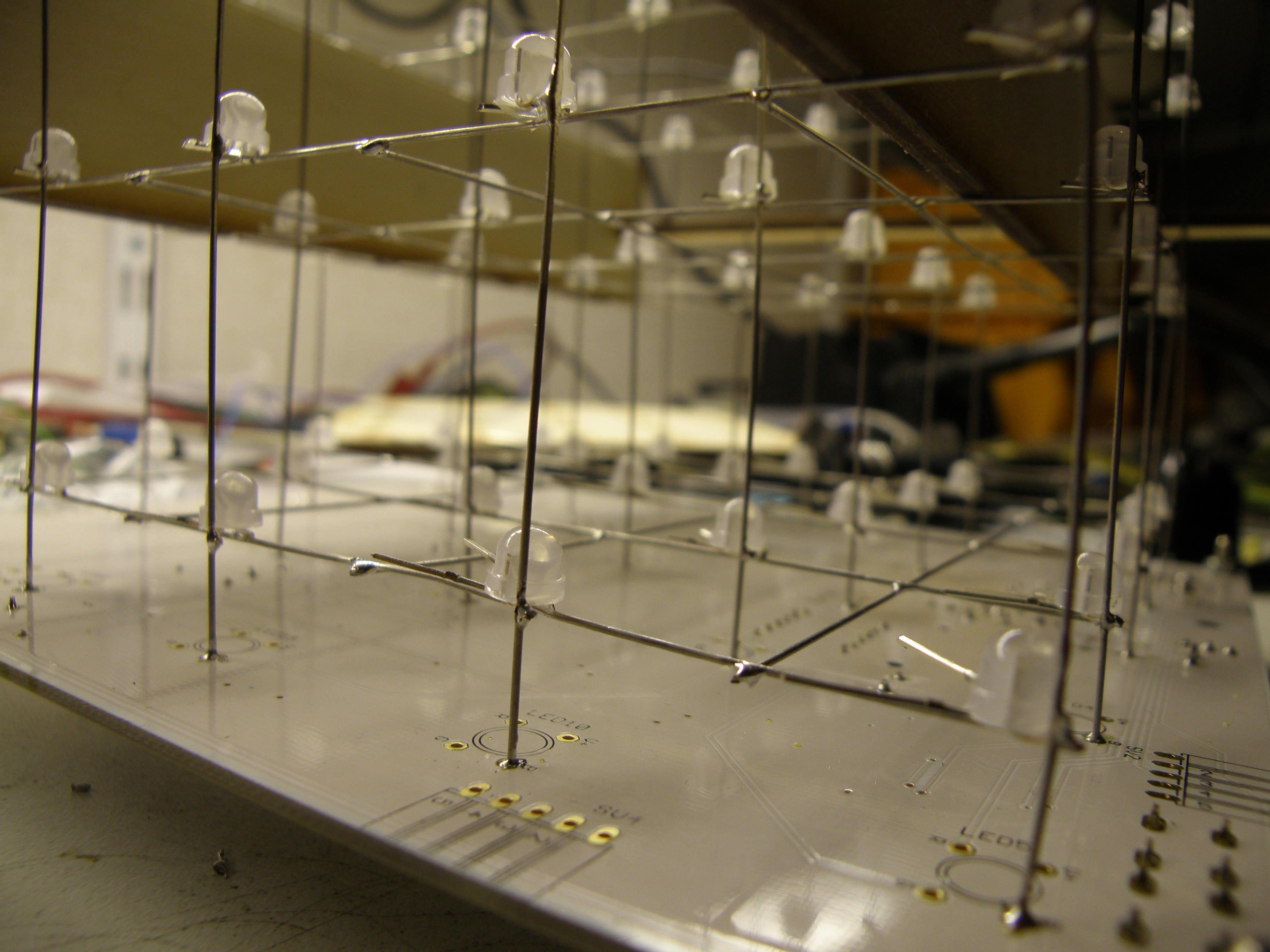

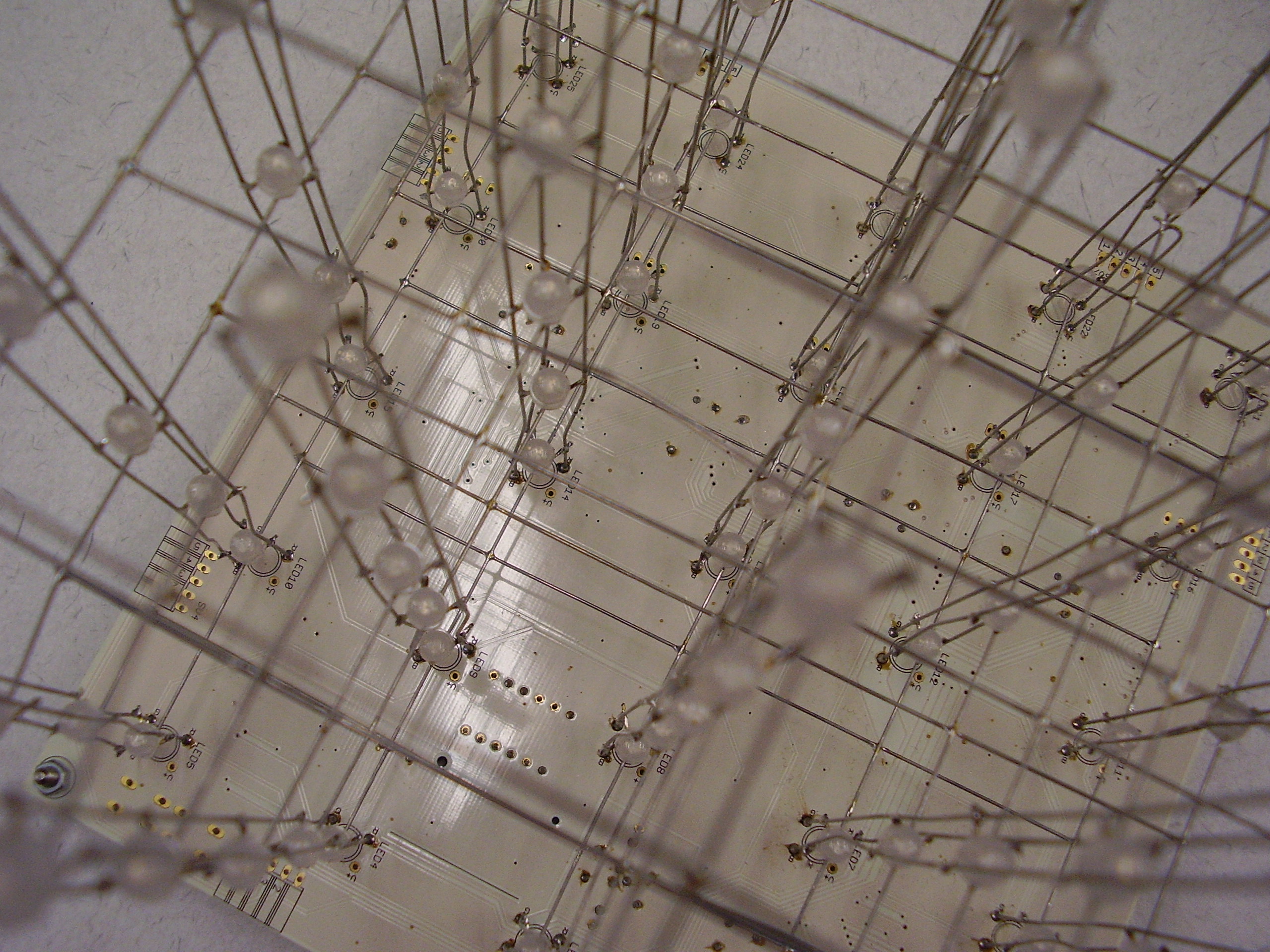

In the second step you needed to solder the vertical wires on the pcb and lower the layers from step 1 over it, holding it at the correct distance with the provided spacer and soldering the RGB pins from the leds to the wires. Repeat this for the other 4 layers.

The problem with this was if you didn’t bend the led pins precise in step one the led pin was not close enough to the vertical wire what made it difficult to soldering it. Bending the led pins a bit was not difficult for the leds on the edge, but the leds in the middle was hard to reach.

Finale finished with the soldering work and after uploading the test program to it…. 4 leds dead, and 3 not at the edge but in the middle.

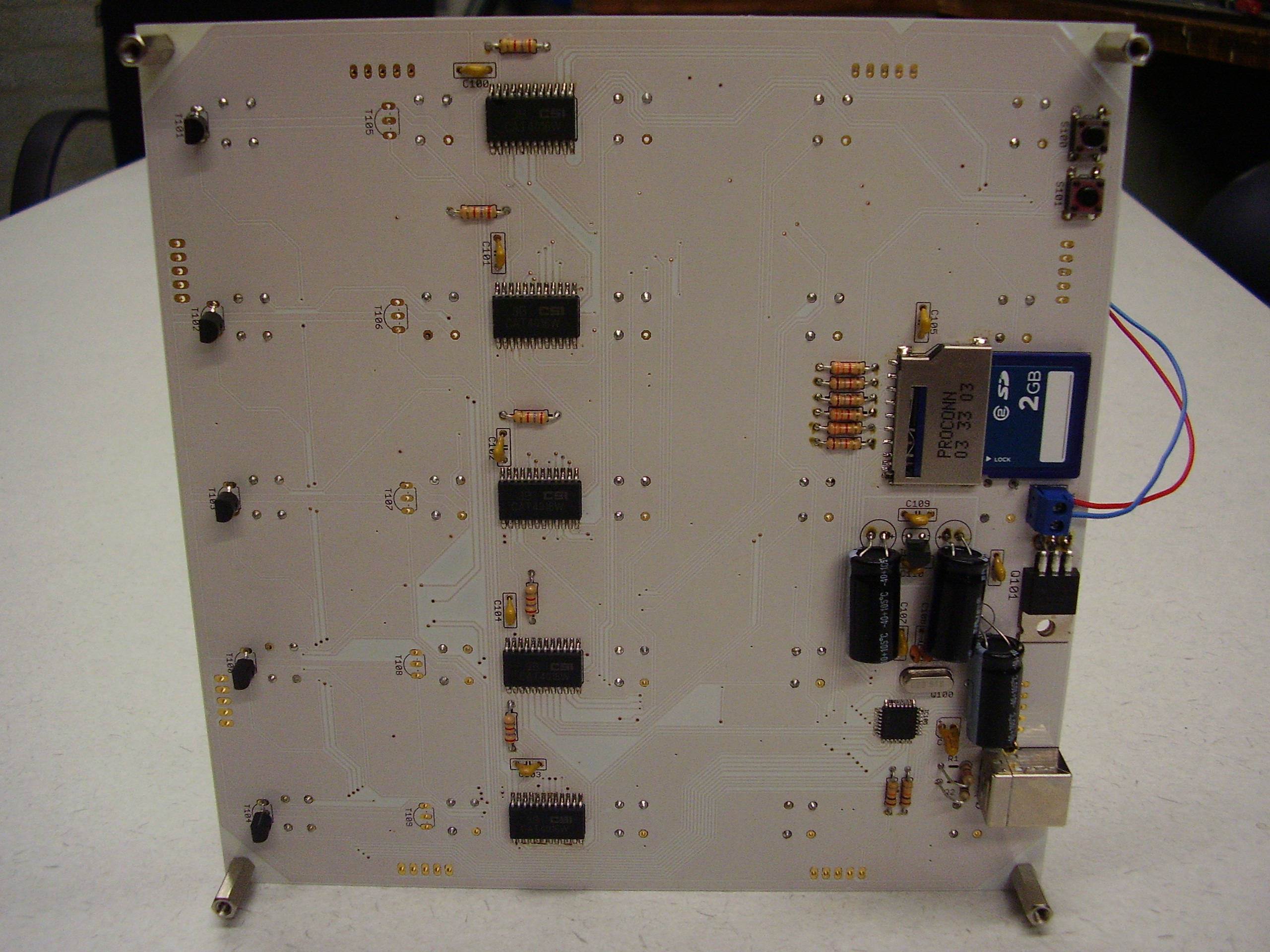

Very hard to get to the leds and replace them. During testing I blew up 1 of the drivers (CAT4016W) due difference in ground potential from my soldering iron. After replacing the driver everything was working fine finally.

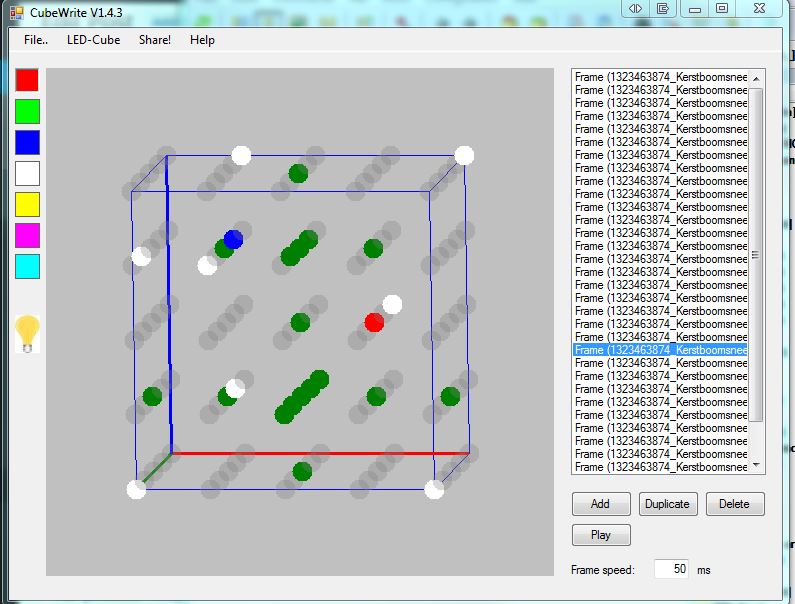

With the provide PC tool you can make your own sequence and upload it to the sd card in the cube.

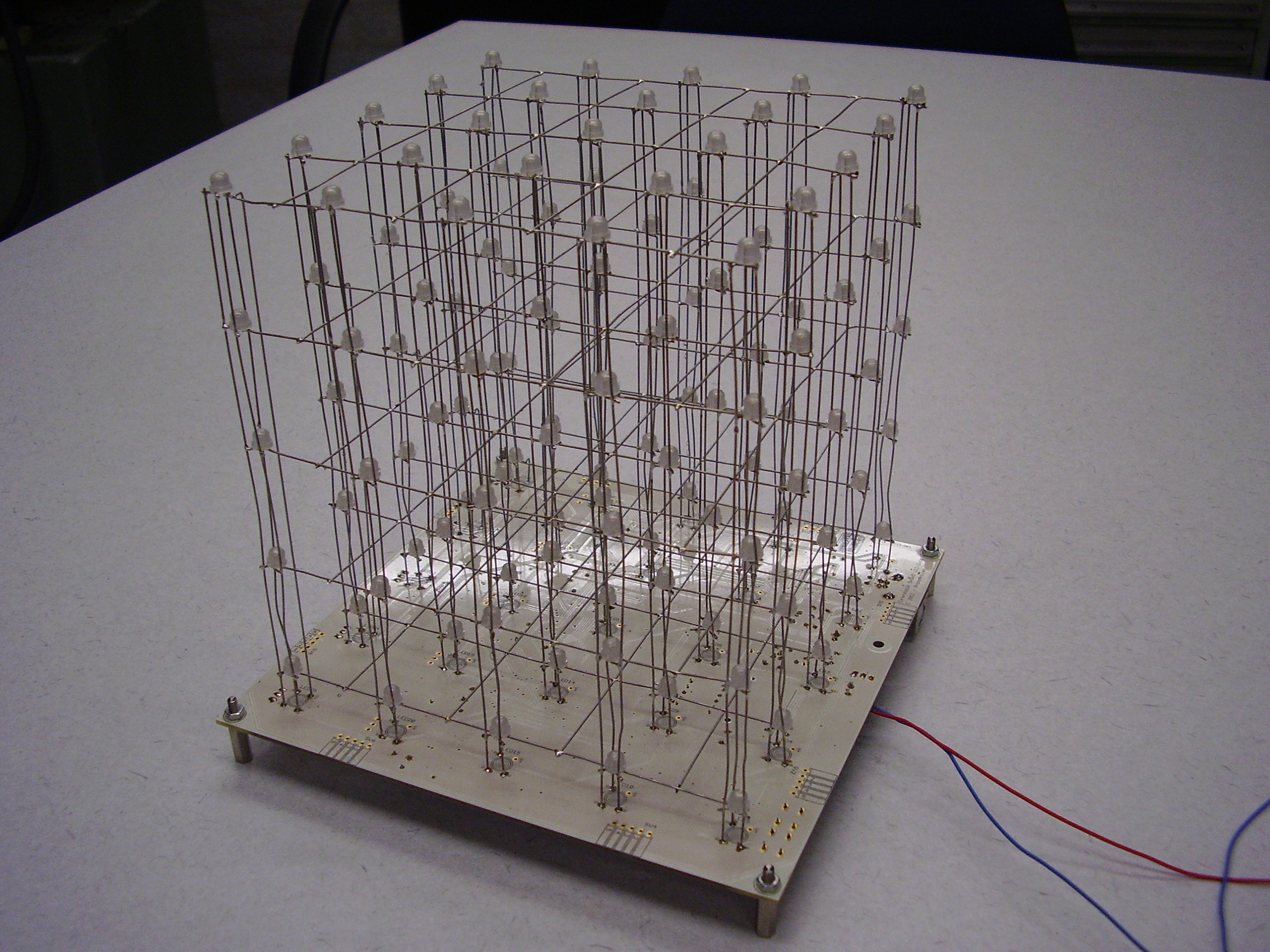

But, not all the troubles where over now. I did bring it to my work to show it to my colleagues and one of them dropped the cube on the floor with the result is was completely bend. Did bend it a bit back but was to anxiously that it could brake. See the result in the Finished picture, this is the result after the drop, befor it was nice straight.

After this disaster the next one was there, somebody used my power supply for other purposes and set it to 12V. I didn’t checked it and switch it on with the result that all the drivers where fried. Back to the soldering iron again to replace them all.

Small impression of making the cube and the result.

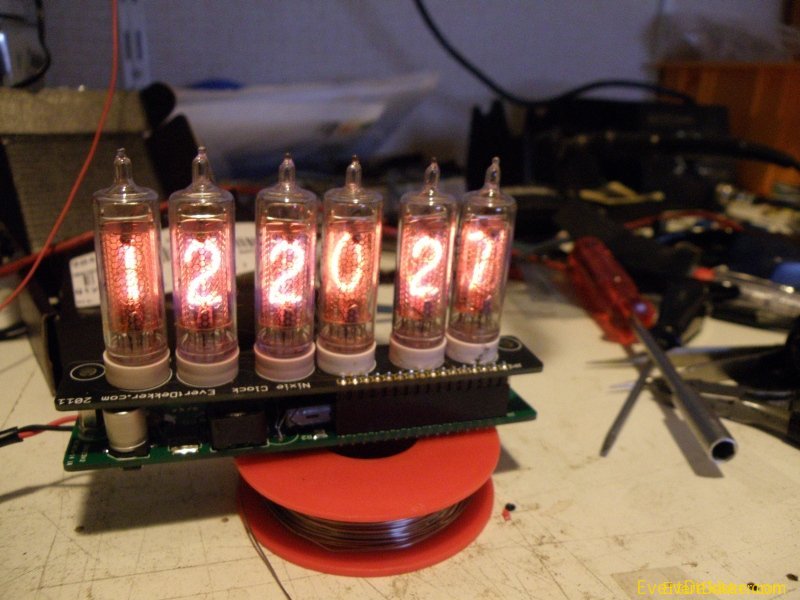

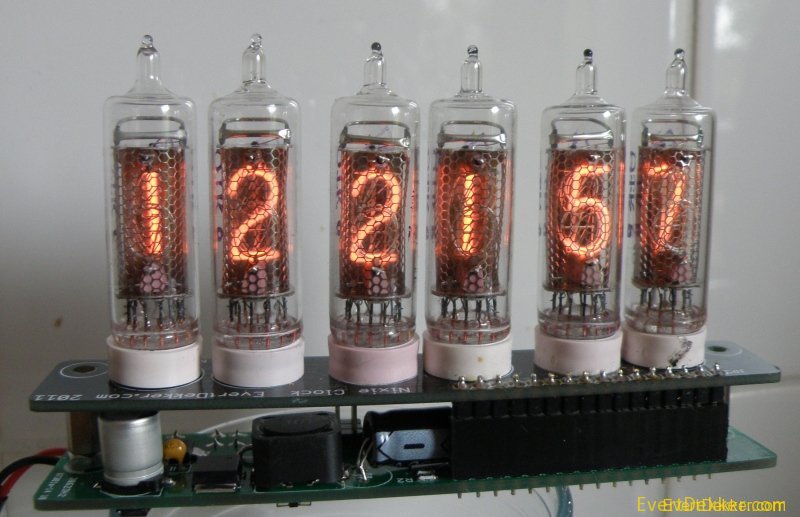

The cube in action. Due the multiplexing of the layers and the camera shutter it flickers a bit, but in real it doesn’t.