Esp-01 Programmer Mod

For a small project of my there was needed a programmer for the Esp-01 wifi module to program the module. It’s not really a programmer, but more an usb to serial convertor.

For a small project of my there was needed a programmer for the Esp-01 wifi module to program the module. It’s not really a programmer, but more an usb to serial convertor.

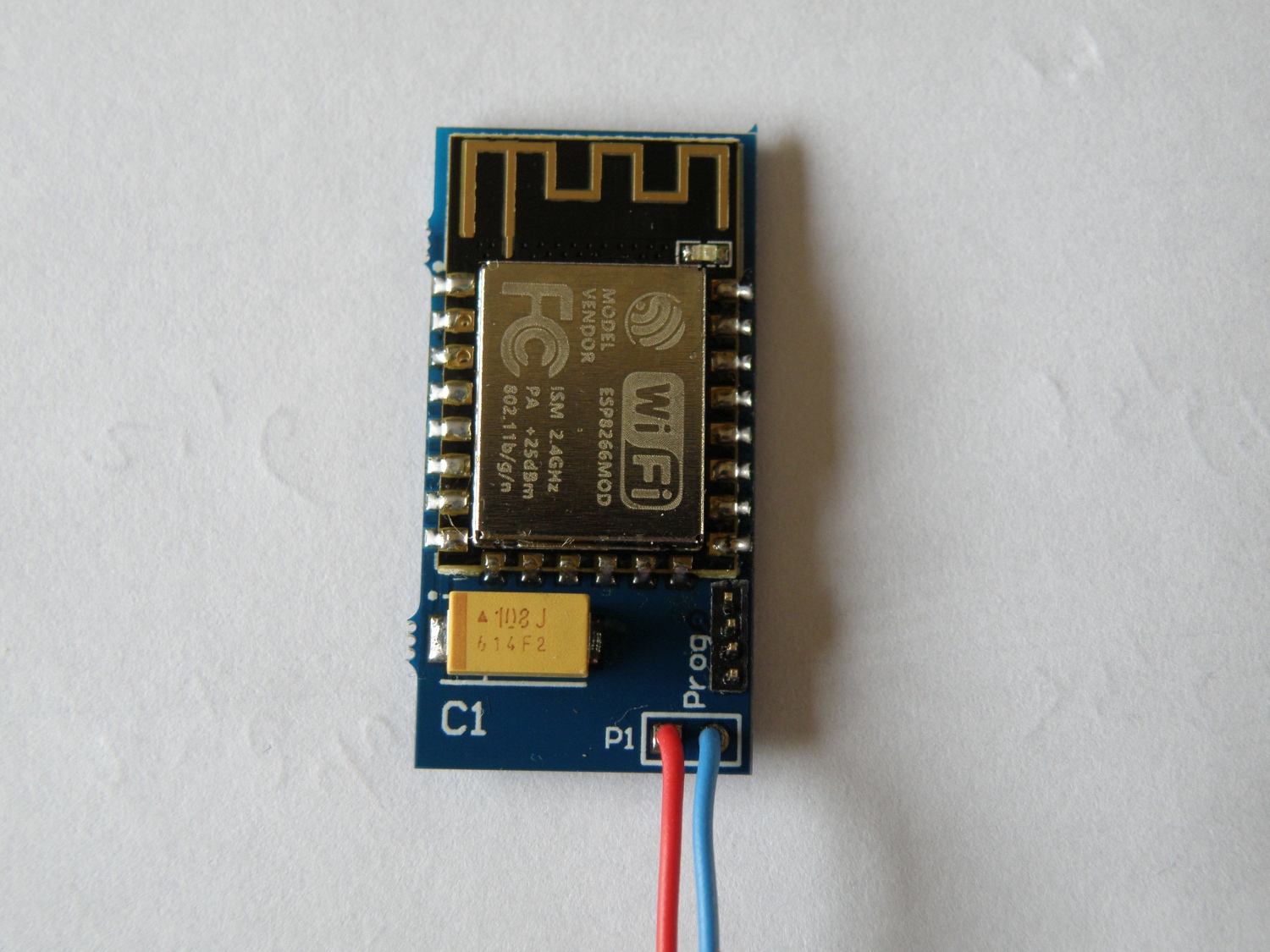

Simple search on Aliexpress gave a nice looking programmer that you can stick in your pc and voila Esp-01 can be programmed, can be bought for $0.78 including shipping.

Bummer, when it arrived and want to use it to program the Esp-01 module it wasn’t possible to get it working with the Arduino ide. The ide was constant coming with the error espcomm sync failed and other com port related errors.

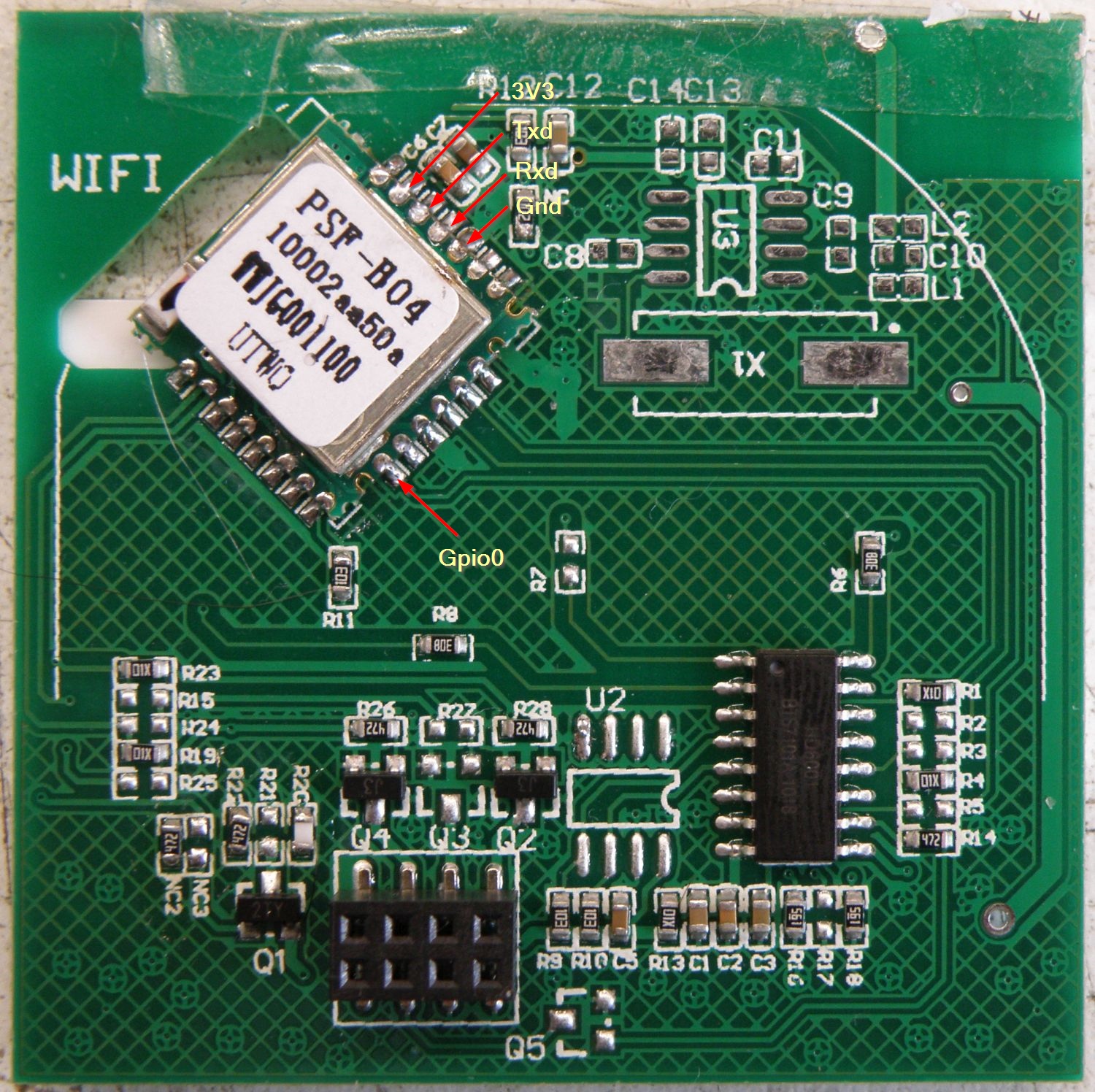

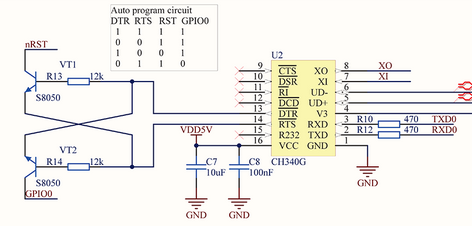

After a quick google search it was clear, the bought Esp-01 programmer works fine out of the box when you use the Esp-01 with the AT commands, but for using it with the Arduino Ide the Esp-01 module had to be set first in programming mode by connection GPIO-0 to ground and reset the module to bring it in flash uart download mode.

Most of the solutions found on the net uses 1 or 2 buttons to get this accomplished, but I wanted automatic programming mode just like the NodeMCU does. Just press upload in the Arduino ide and go….

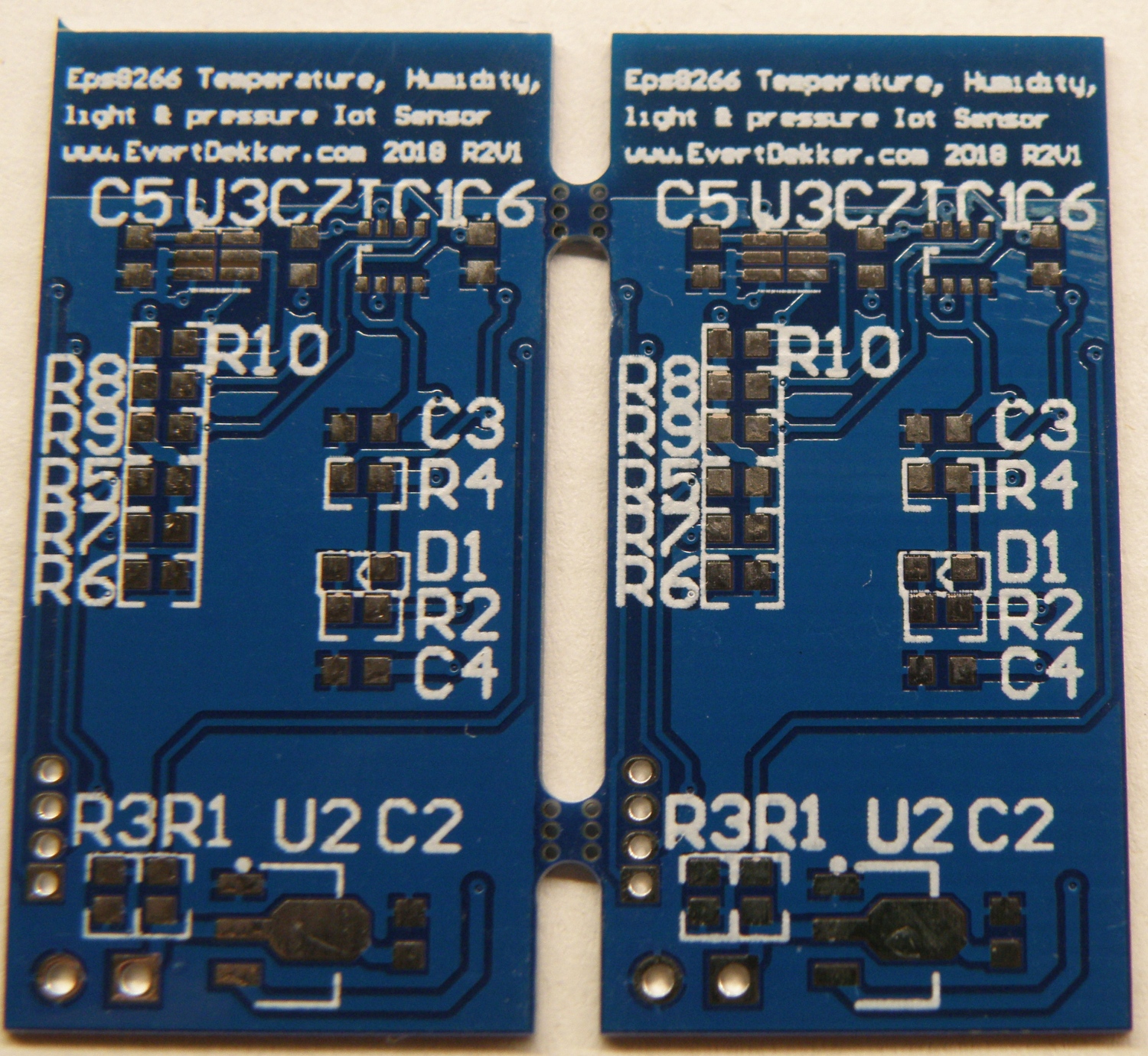

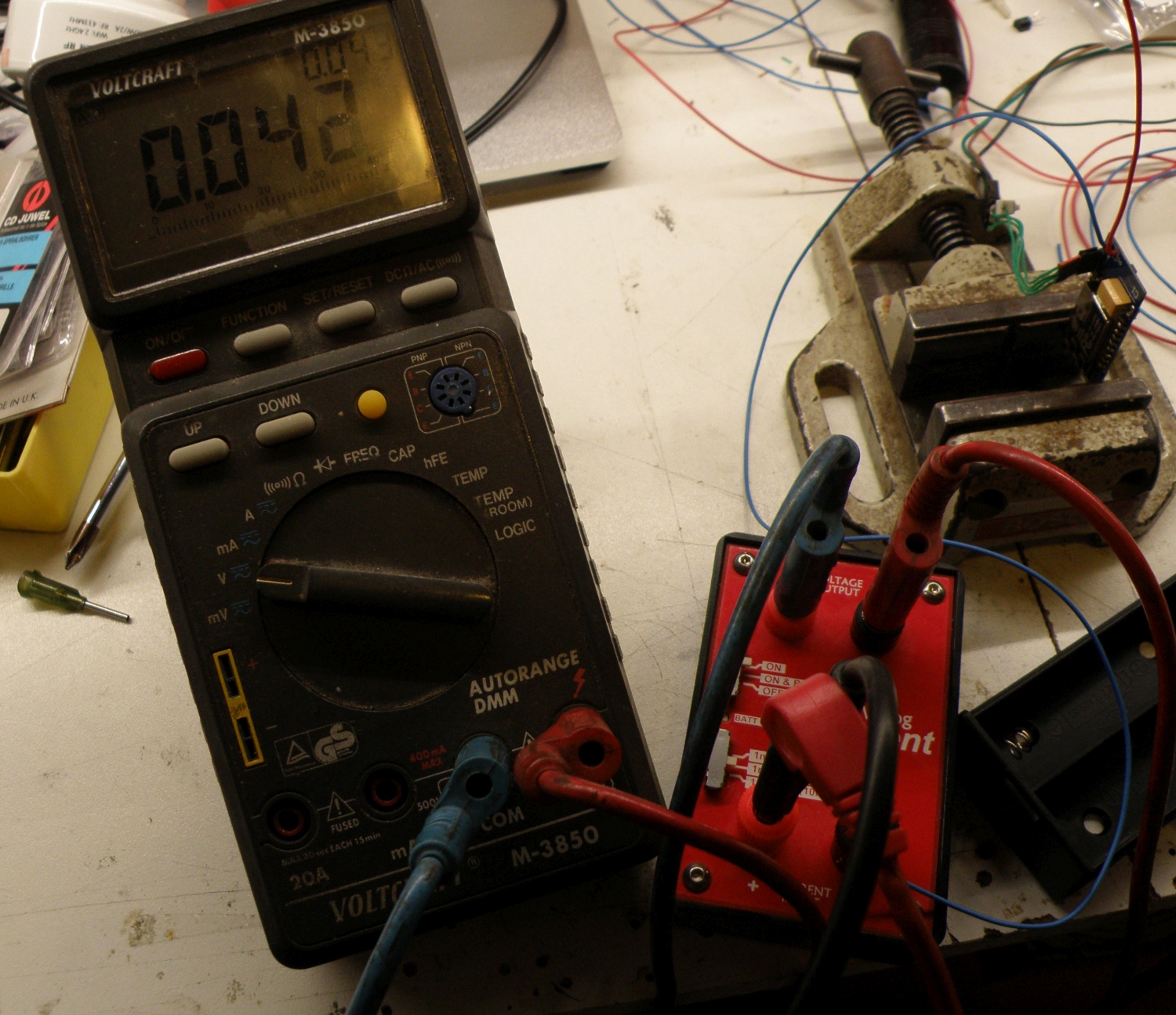

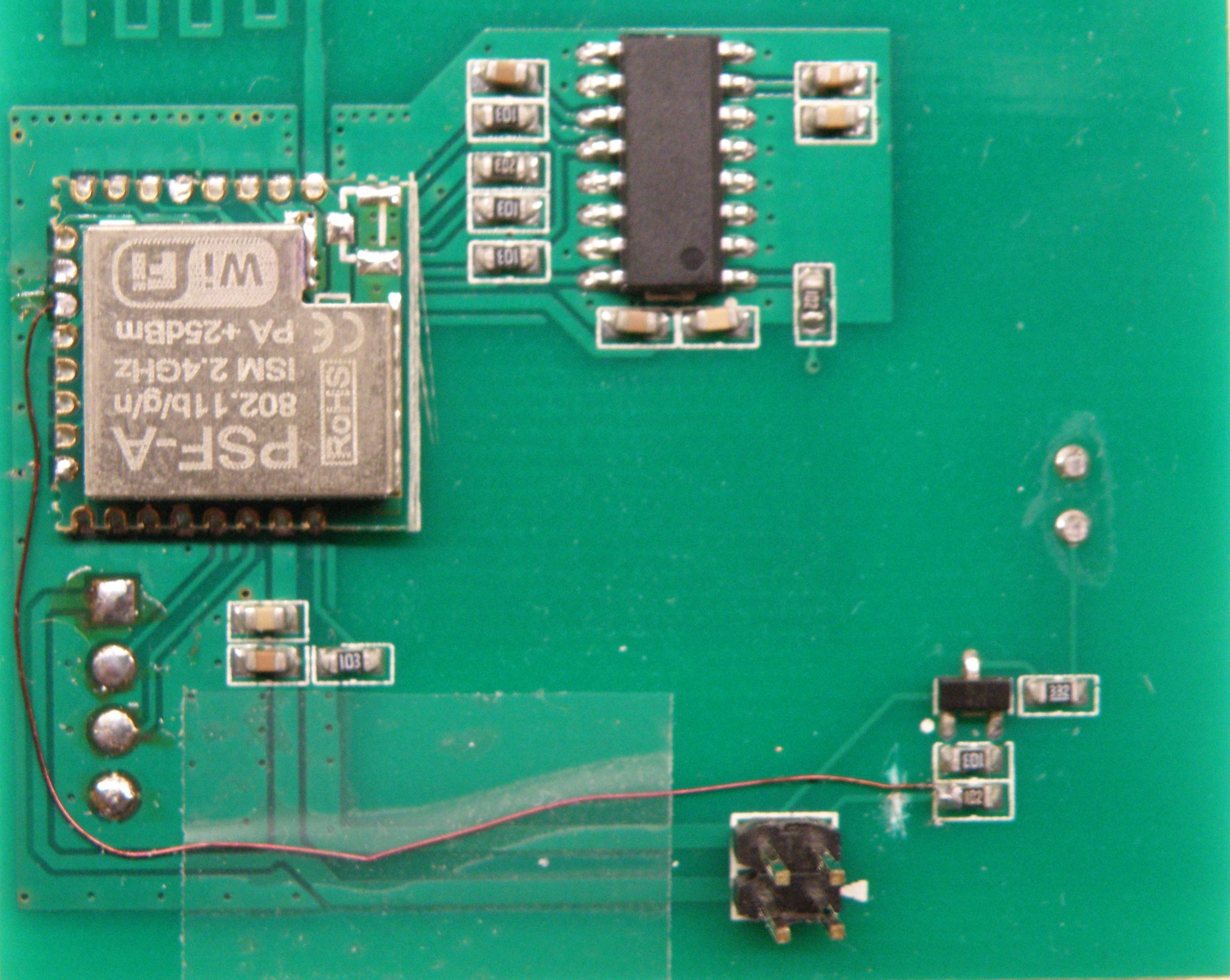

The programmer uses the same usb to serial convertor (CH340G) as used in the NodeMCU so it should be possible to use the same schematic. The Arduino Ide already supports the NodeMCU so no need to change drivers, board.txt or platform.txt files.

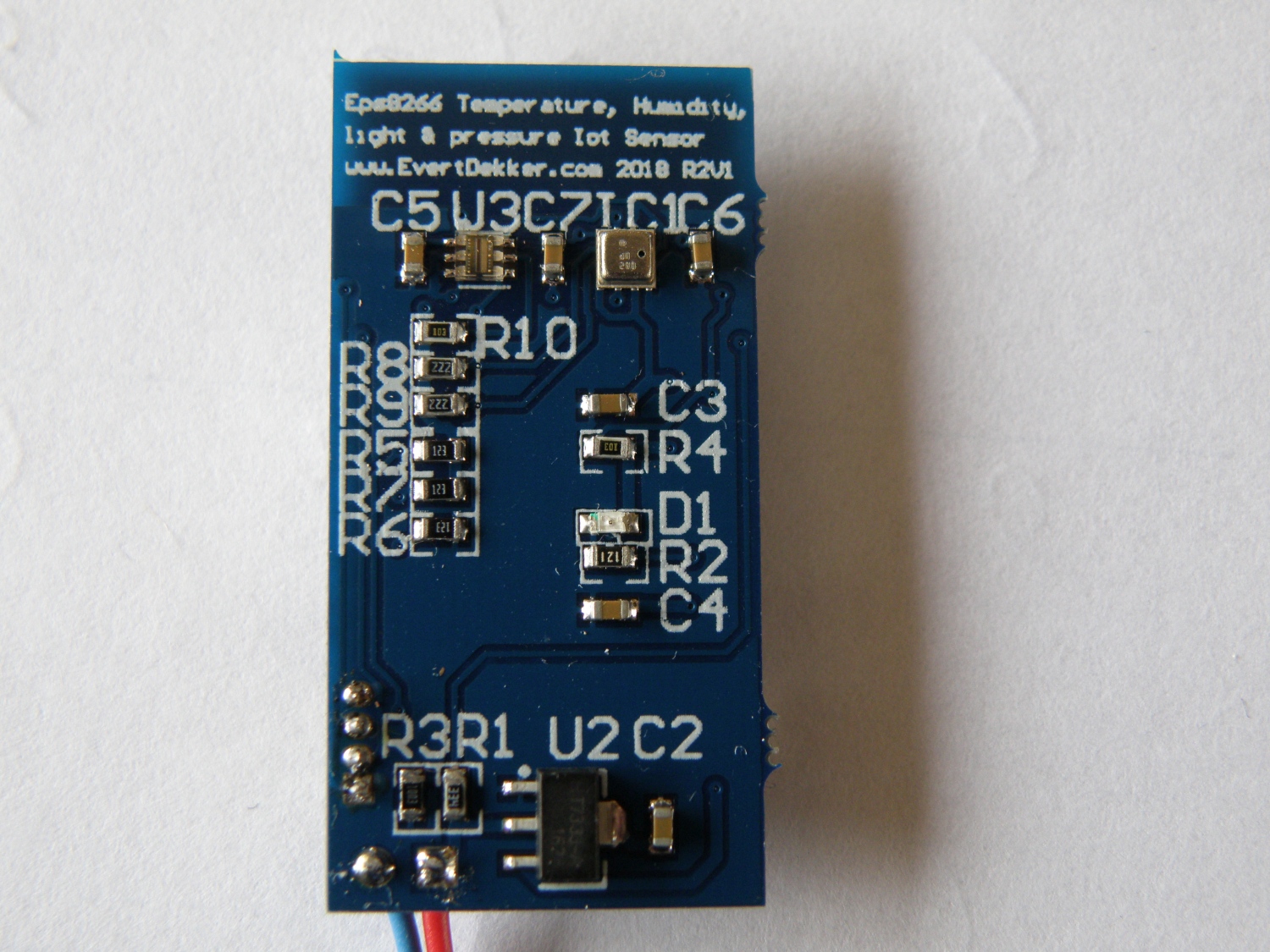

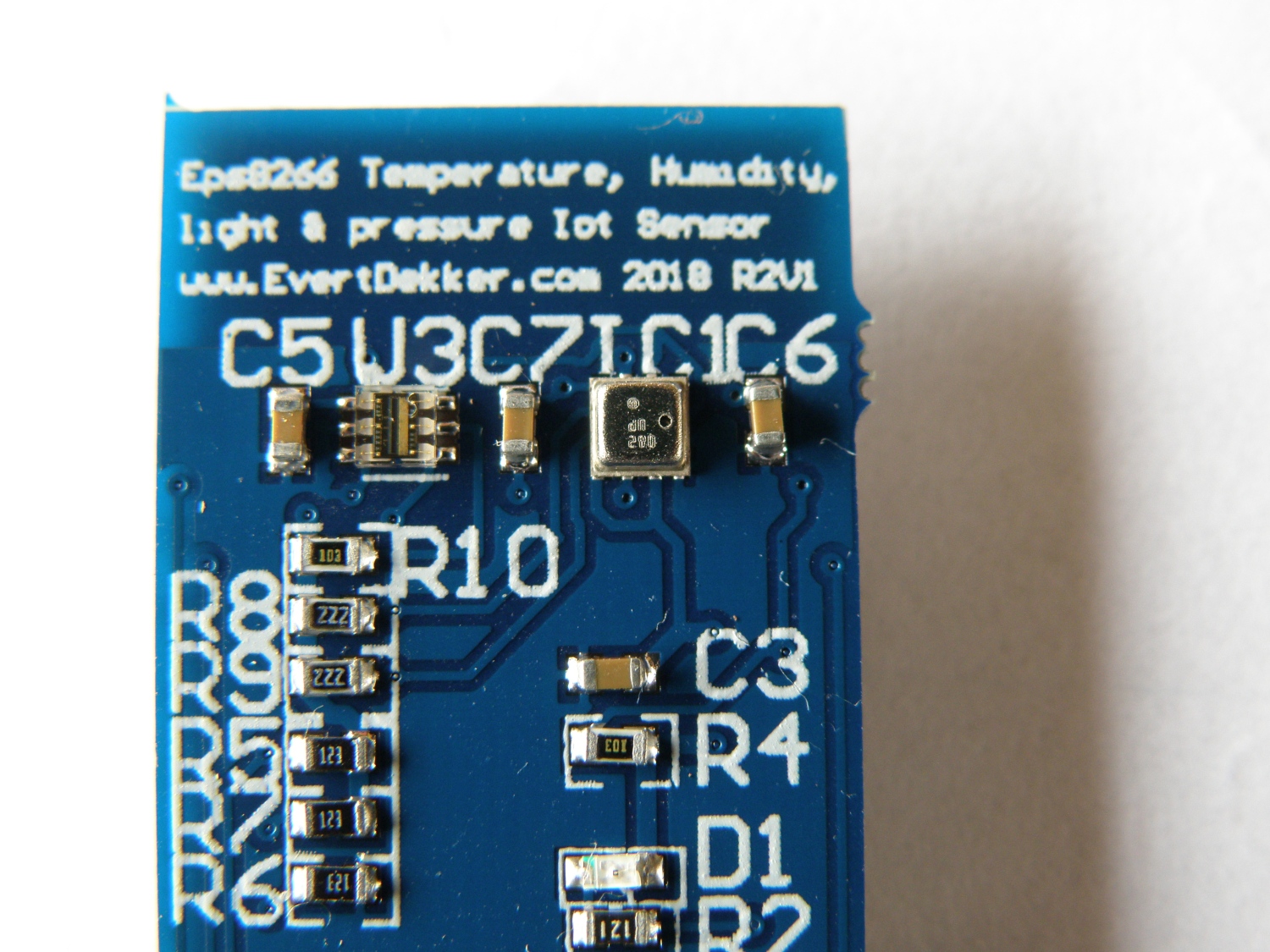

The part that’s responsible for pulling GPIO-0 low and resetting the Esp-8266 is only two general purpose npn transitors and 2 resistors.

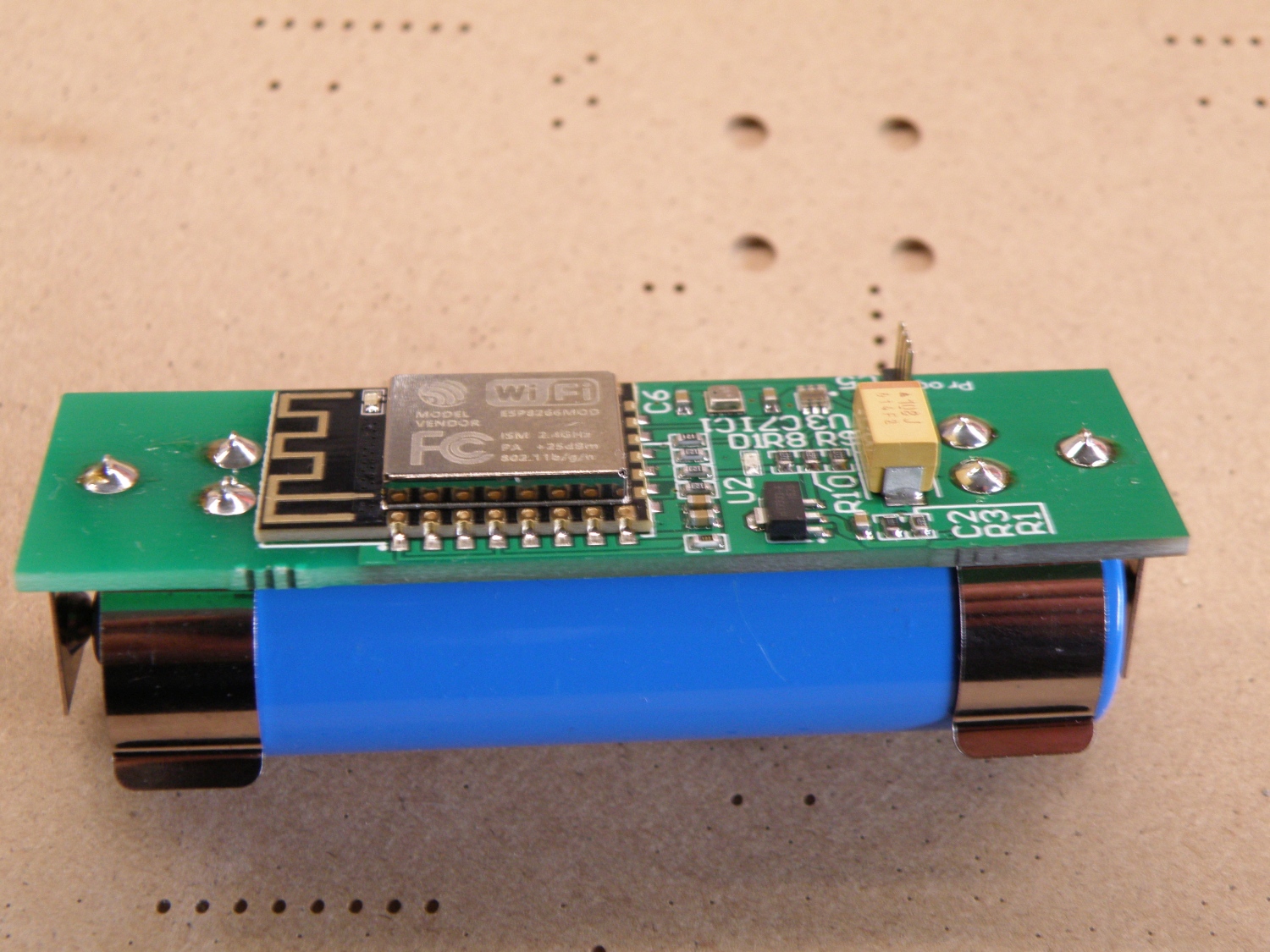

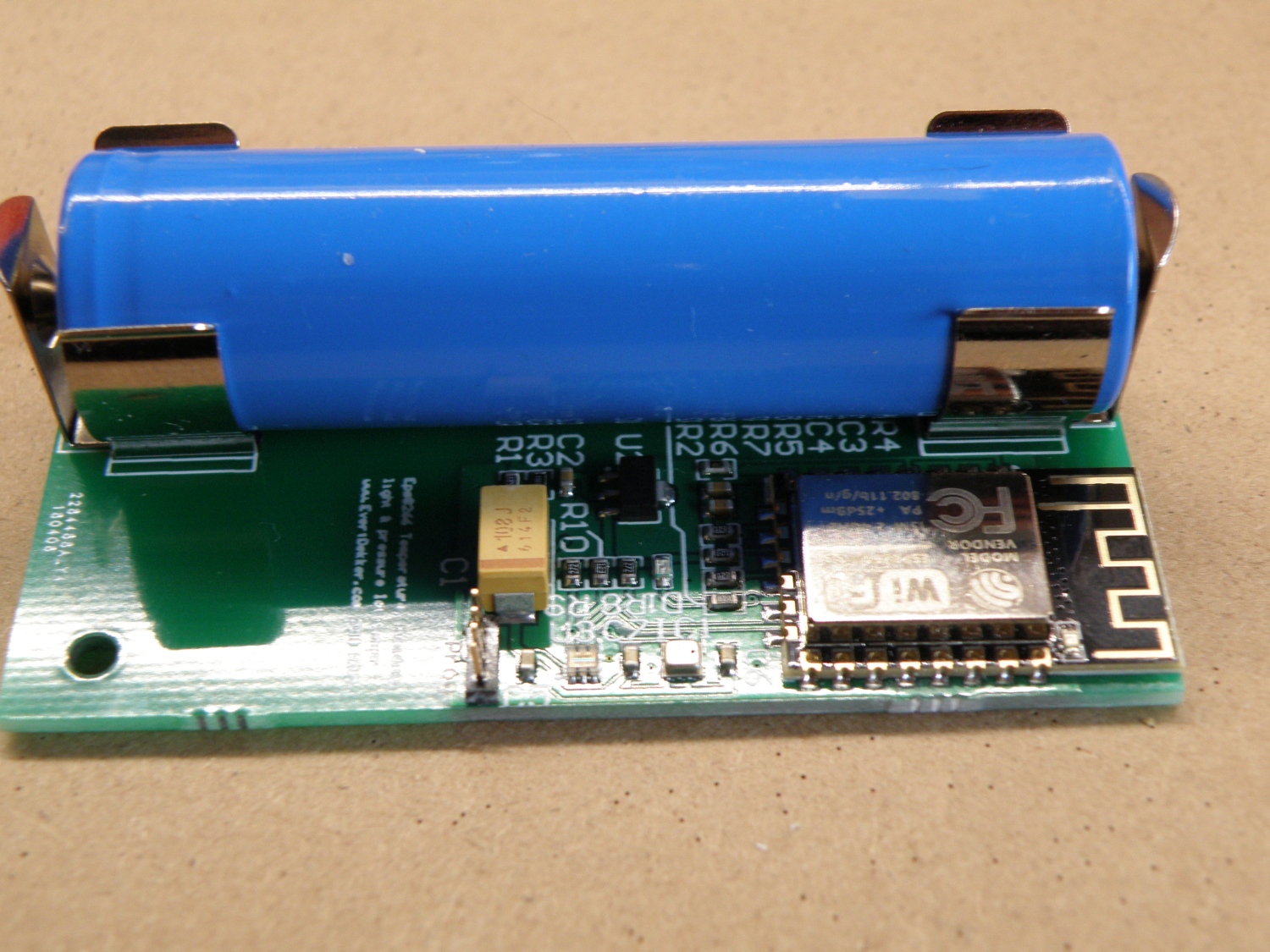

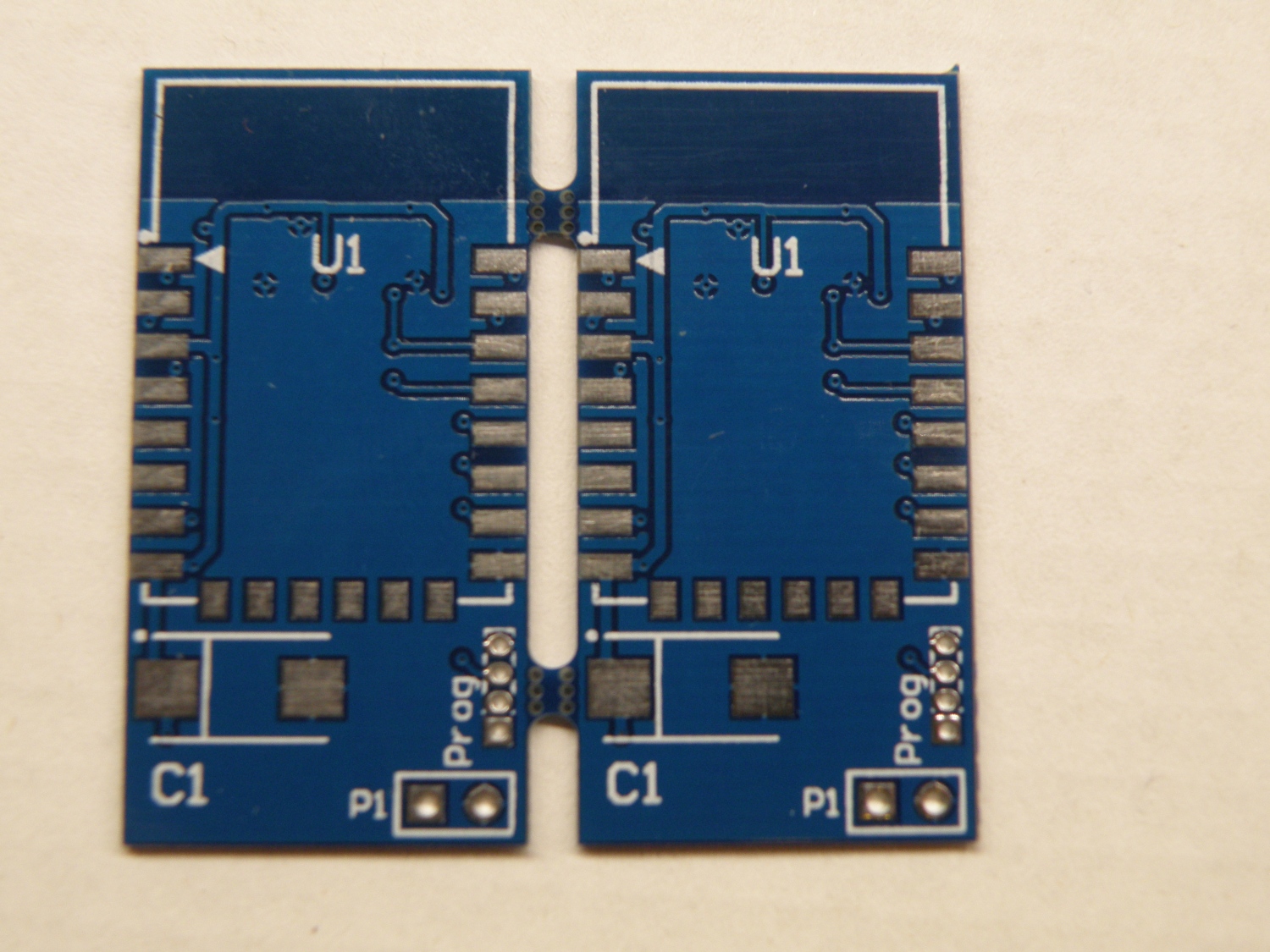

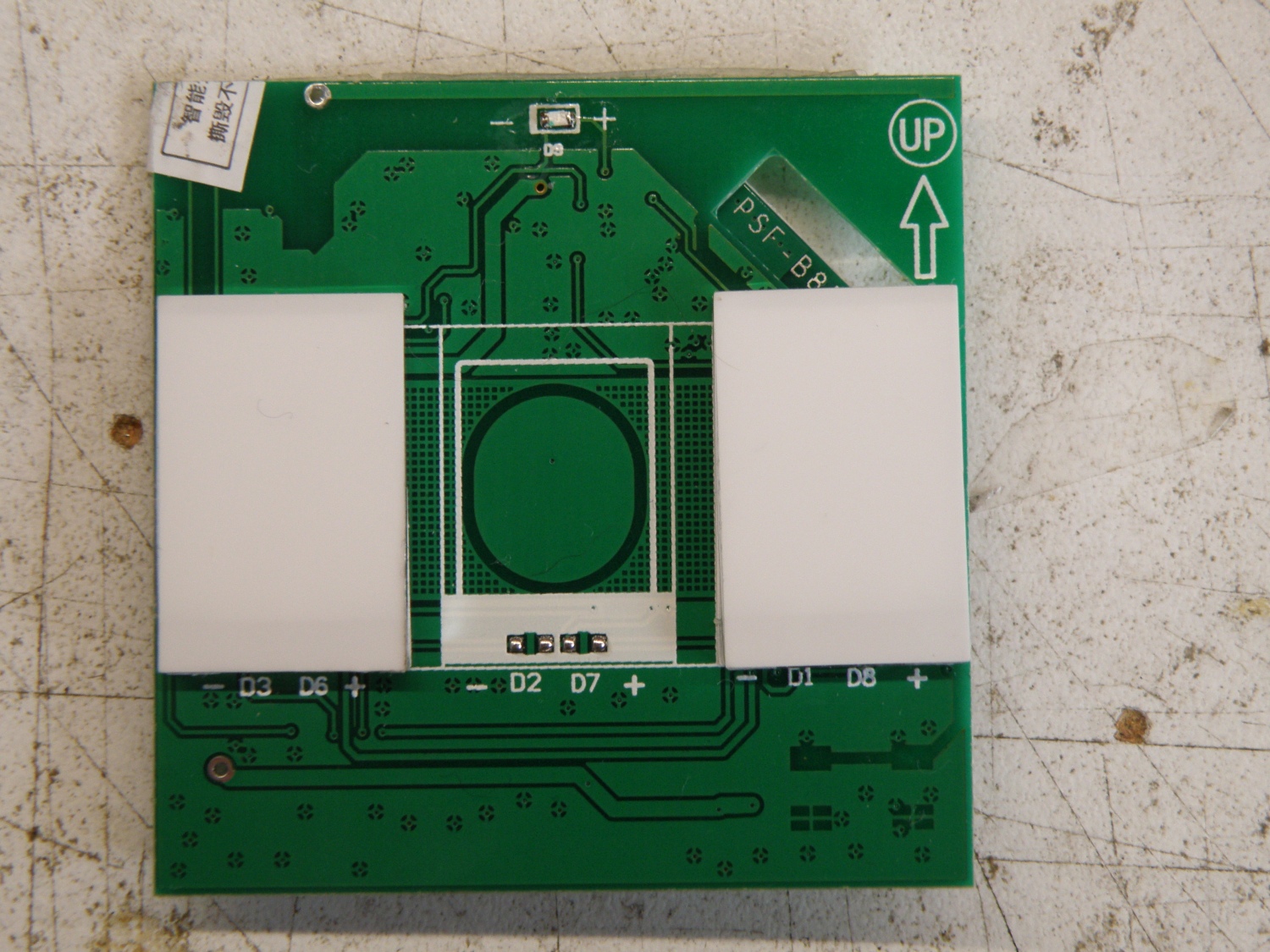

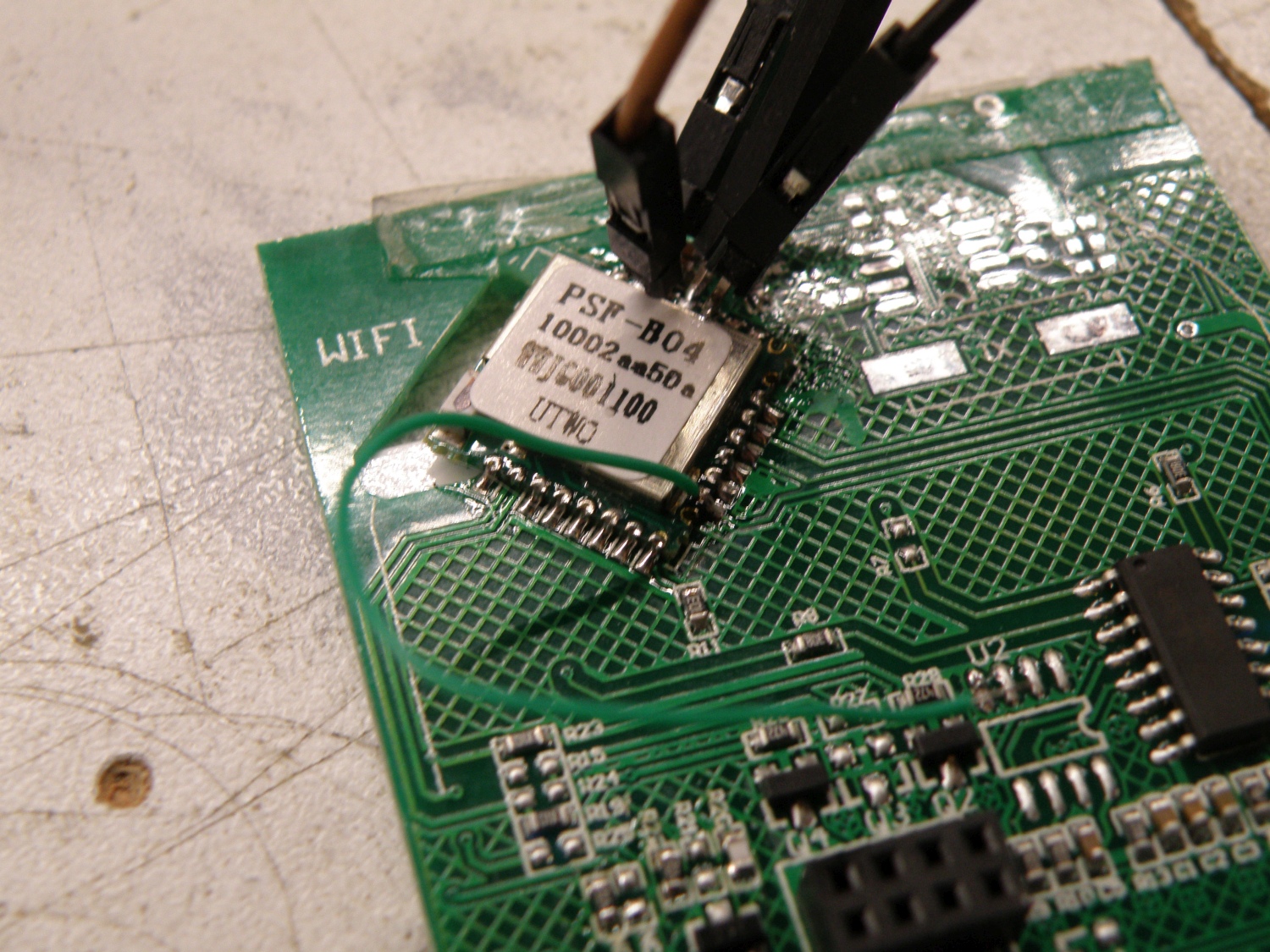

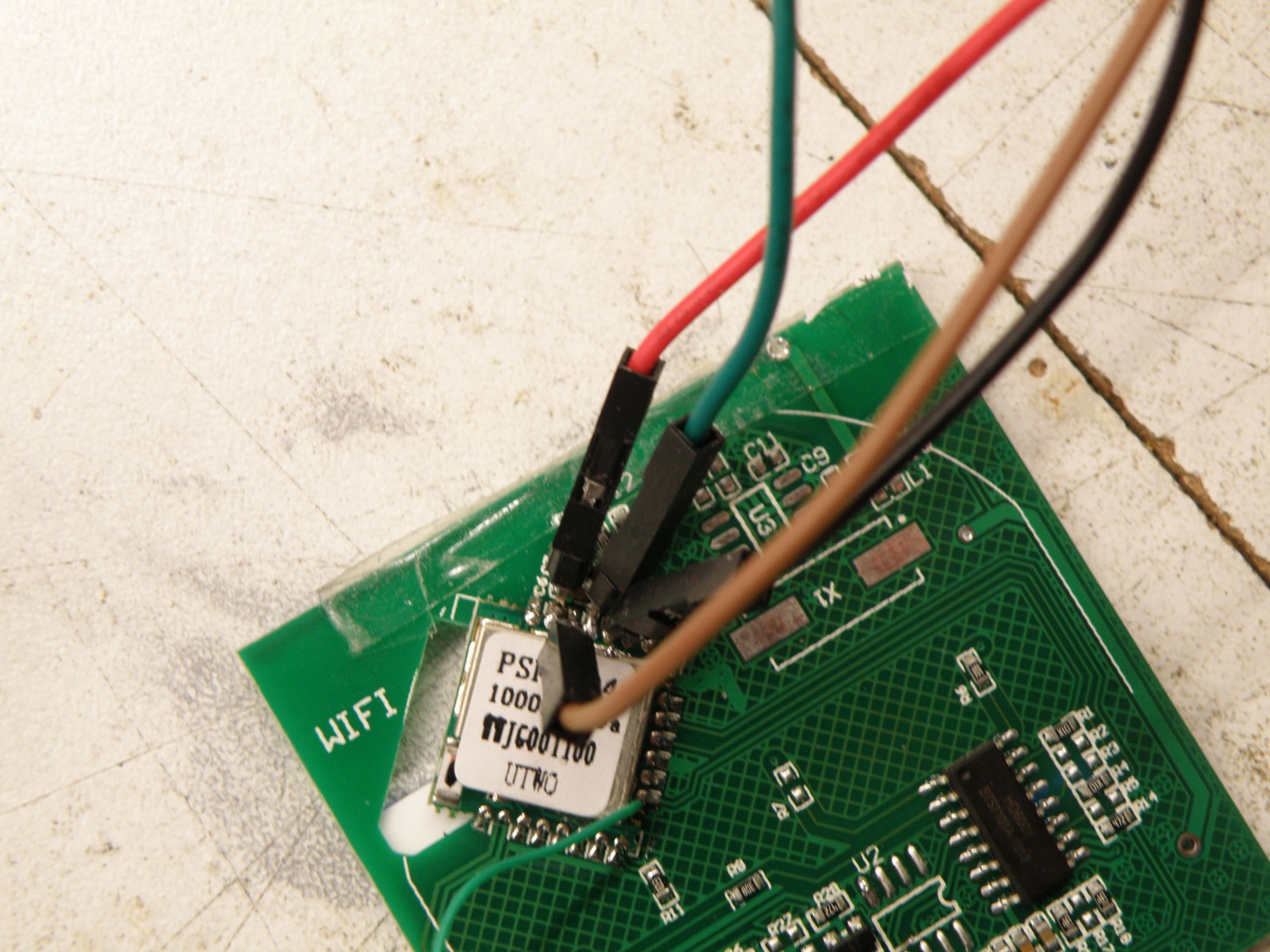

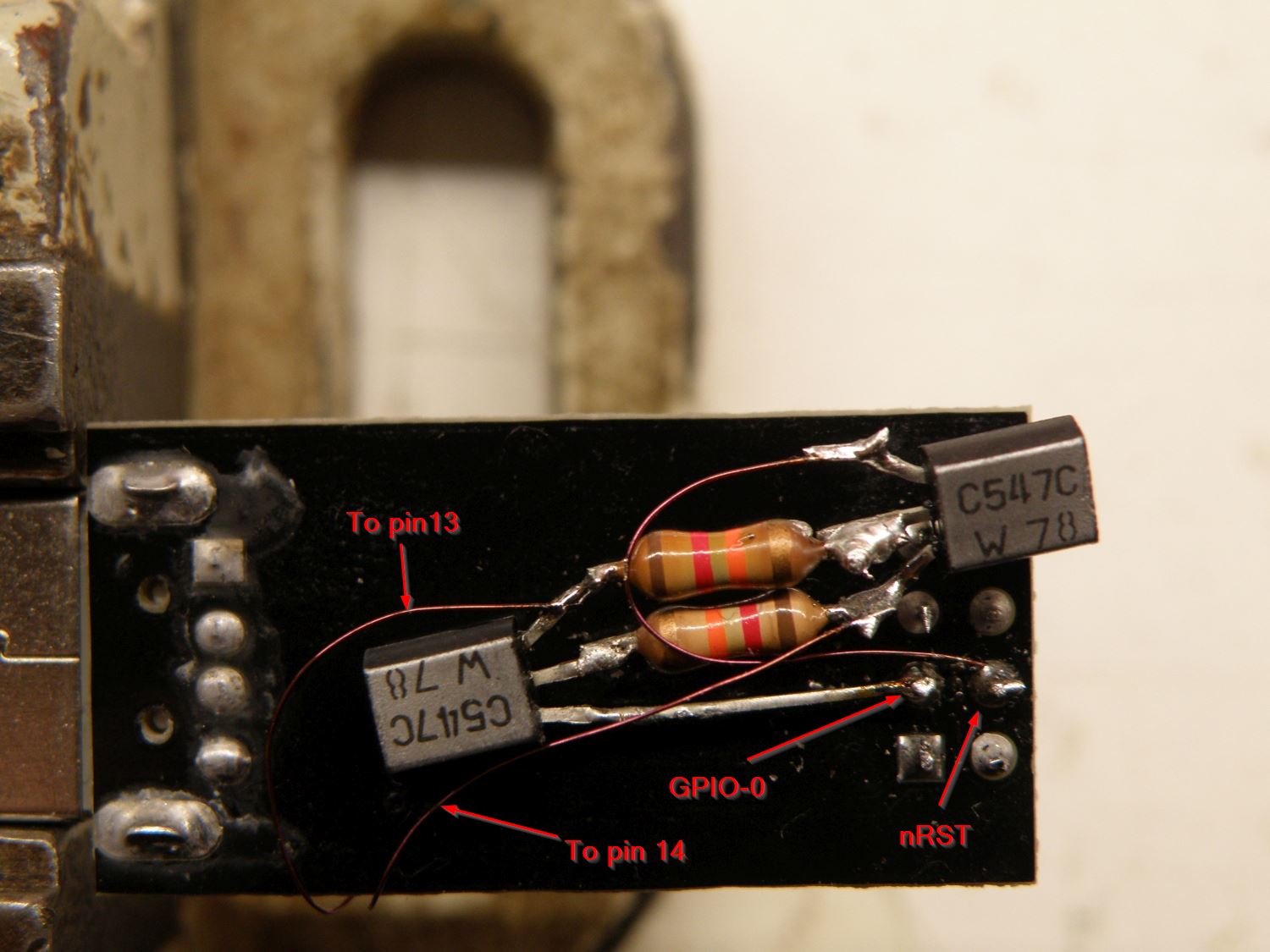

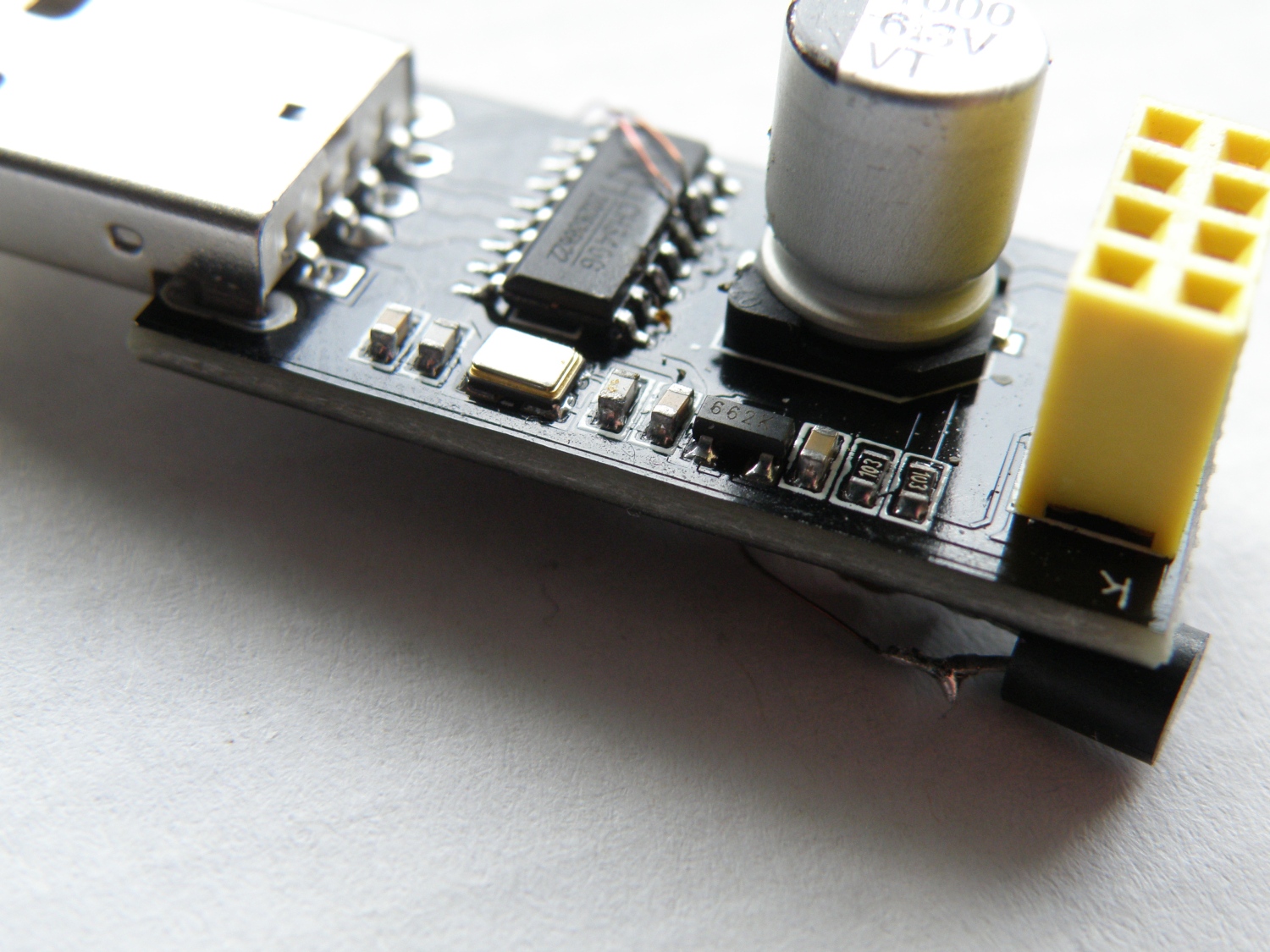

So I added 2x BC547 (or use any other general purpose transistor) and 12K resistors to the bottom of the programmer board. It’s not my best soldering work, but it will do the job.

Soldered 2 wires to pin 13 and 14 of the CH340G and connected them to the transistors on the other side.

You can fix everything with some hotglue if you want.

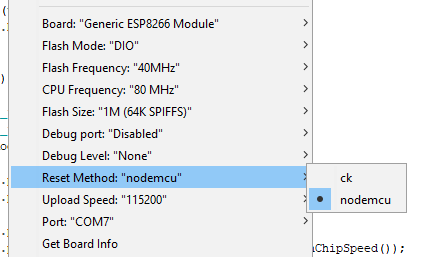

Change in the Arduino ide the setting Tools , Reset Methode to NodeMCU and you are ready to go.

Every time you press now upload the Esp-01 will be set in serial download mode and you can upload you fresh developed code.

Happy programming.